It is not uncommon that customer have real light bulb moments in the course of the analysis process of a supply chain consulting project. Companies rarely question the status quo of the daily business as long at it is running. Often managers and employees even become routine-blinded. In the analysis phase it is important for the consultant to get to know the customer, understand his business processes and recognize the potential for optimization. We are sometimes surprised how the customer is suddenly able to see his business and processes from a totally new perspective because of the deep dive provided through the dialogue we are initiating.

Analysis first, consulting second, implementation third

The stage of analysis is an extremely important one and usually it is as extensive as the subsequent consulting process. In addition to getting to know and fully understanding the customer and all supply chain processes, we pay particular attention to uncovering (hidden) operational potential. We set into relation the so-called "logical supply chain” and the "physical supply chain” and identify gaps that need to be closed and optimization potential that has to be realized. Every company acts and operates differently. Even within an industry, supply chains are not organized in standardized schemes. This fact makes it very exciting every time we are stepping into a new supply chain consulting project. At the beginning you have no clue about what will turn up when having a closer look at the supply chain. There are always supportive and challenging surprises.

Mapping the status quo

Is the supply chain following international best practices? Is the supply chain ready to face future challenges? Which weaknesses need to be overcome and how can the supply chain be improved in terms of processes and technology?

Answering these central questions is important and should be the outcome of the analysis. Usually neither the customer nor the consultant are able to answer these questions straight away. We work our way through a structured analysis process until we get to the core of these questions. The following steps represent essential milestones:

- Material flow: What does the existing material flow look like within the entire network? We define the "logical supply chain” and set it in relation to the "physical supply chain”.

- Order processes: How do order processes work and which areas are involved?

- Organizational structure: What does the organizational structure look like and how is the supply chain integrated within the organization?

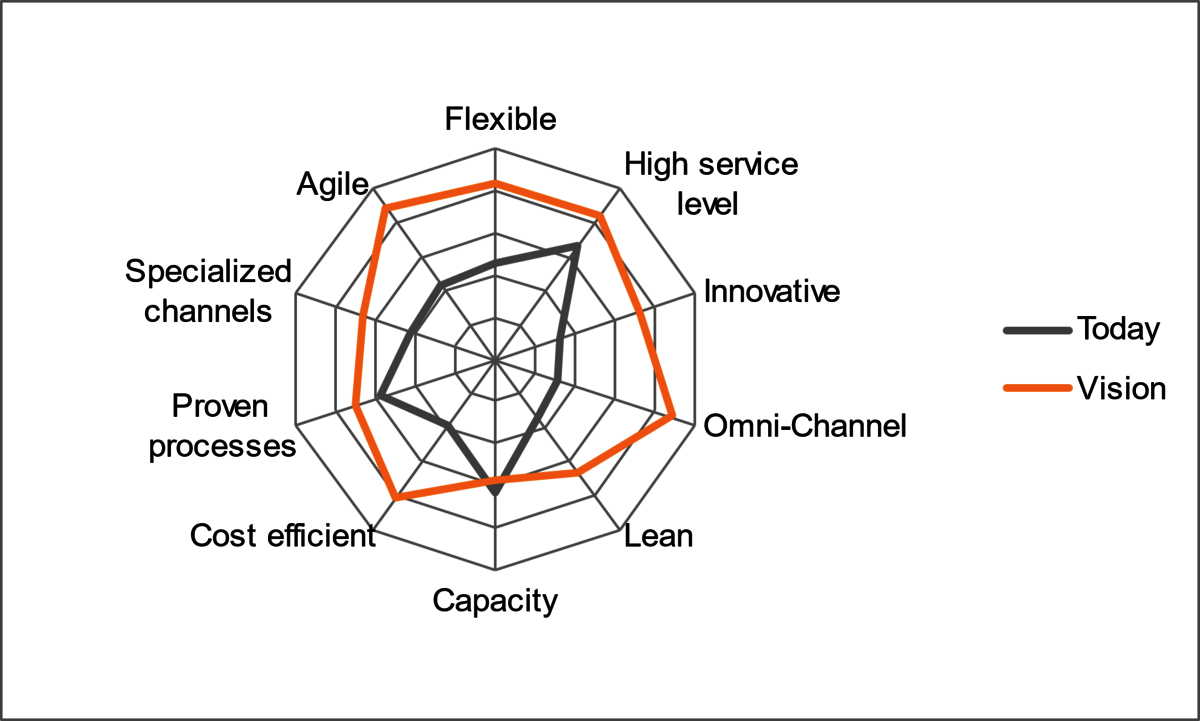

- Strengths and weaknesses: Together with the customer we unveil strengths, weaknesses, opportunities and threats of the existing supply chain (SWOT) and visualize them graphically by using the supply chain radar.

- Future outlook: We try to identify future requirements by having a closer look on the business plan, the overall supply chain strategy and the recent business development.

- Site inspection: An essential part of the analysis is an on-site visit at the warehouses and retail spaces of our customers and their suppliers. Our teams speak to relevant key people from the various departments within the organization and get a live demonstration of the processes in real time.

- IT landscape: In addition to the processes, we check the entire IT landscape. Which internal and external systems are used to map stock management, order management and transport management, and how are they interlinked.

The outcome of the analysis is always a strategic and structured catalog of measures that relate to the customer's objective – the "Magnificent 7".

No measures without having the goals set

Companies get in touch with LNConsult as a supply chain consultant to further develop their existing supply chains. There are many reasons for this, however, the motivator for change and improvement can be either a current challenge or the preparation for a future scenario. Challenges which have to be faced with respect to the supply chain often are linked to existing processes that do not run smoothly, efficiency that needs to be pushed, the throughput that needs to be increased, the costs that have to be reduced, the error rates that have to be eliminated or in general the capacity that has to increase. Other customer projects are more future oriented and focus on the idea to prepare the existing supply chain for a growth scenario that lies in the future. The question then should be: How does the supply chain has to be organized to fit the scenario of tomorrow and which steps have to be taken today to get ready for this change.

When the moment of truth becomes a moment of surprise

Customers of LNConsult not only benefit from the Magnificent 7 that highlight the pathway to sustainable success, but also from state-of-the-art processes and technologies. Of course, the proposed measures are not always implemented by the customer. However, customers are often amazed that there lies a lot of optimization potential even in quick fixes.

Customers are often surprised when we are not recommending high levels of automation to them. Sometimes it is not even necessary to implement new technologies, but simply to use the existing resources correctly. There is often a great bundle of unused potential in companies that "only” has to be activated. It is not surprising for us to come across technologies that are used incorrectly or not at all by the customer. On the other hand, many customers invested in technologies, that are absolutely not suitable for their processes.

It is exciting to see how the customers' perspective on their own business changes when we work together in the analysis process. Asking the right questions and also questioning things that seem to go well are two of the most important skills of our experienced consultants.

We love the bulb light moments of our customers! Marko Pleteršek, Head of Operations

Celebrating the light bulb moments

To be honest: We love the bulb light moments of our customers! They are often referring to results in areas, where the customer has not even thought about an unveiled potential or that are absolutely unexpected. We experience this especially when we present facts and figures that make a hidden potential even more tangible. In one project, the customer was very sure that processes were running very well and all potential was exploited as they invested in optimizing those processes in the past. In our supply chain analysis, the project team was able to detect another 30% of savings potential on top.

Most of the time supply chain and warehouse processes do not run as smooth as the customer estimates. Structured data sometimes provides a completely different picture than the employees are expecting. We recommend companies to internally carry out process analysis and optimization measures on a regular basis – but the truth is that only a very small number of companies follow that advice. Even if companies know that things are not running smoothly, they usually need a neutral external party that helps to tackle this complex issue.

It is a pity if customers are not able to implement the developed measures due to limited resources in the end. But the transparency gained through the analysis process already bears a lot of potential for supply chain improvement. And these daily light bulb moments from our customers are making us as happy as the big ones that not only increase, but even redefine efficiency.